CE Pre-amble

To enable countries in the European Union to trade successfully across boundaries, all industries have to operate under the same conditions. This required the introduction of harmonized legislation across the member states. Although it meant new or revised products, industry practices and standards, the legislation has had the effect of establishing common minimum standards for trade and safety across the European Union.

For this to happen, the European Commission embarked on a policy of harmonization. Initially the Commission proposed Directives, which would identify a unified approach to the production and trade of products and goods across Europe. These Directives were prescriptive and it was felt that this was detrimental to both innovation and invention. To counter this, the Commission introduced the New Approach Directives (CE Directives). These Directives are not prescriptive and lay down minimum criteria for compliance. The aim is for the New Approach Directives to be similar in format for ease of reference and use. Perhaps the most significant aspect of the new legislation is the conformity assessment procedure (the means by which the compliance is ensured). The Directives offer a flexible approach, mainly based on trade and safety. Products from around the world can be sold in Europe, but they must meet the Directives and be safe (for example toys).

When a New Approach Directive has been adopted by the Commission it is a legal requirement for each Member State of the European Union to introduce the Directive into its own legislation. These Directives are integrated within the Member States legislation, which necessitate amendments to the existing legislation to enable a co-ordinated approach to be adopted.

Since 2008, the EU has introduced the New Legislative Framework (NLF), this continues the ‘New Approach’, however Directives are being replaced by Regulations. Where Directives may be modified by Member States when introduced to their legislation, Regulations are adopted as written. EMC and Low Voltage are amongst the Directives now aligned to the NLF. The NLF is intended to speed up introduction of new Regulations and increasingly adopt digitalisation.

The Machinery Directive 2006/42/EC is in the process of being rewritten and will be aligned with the NLF, the new Directive is expected to come into force in 2026

The Commission projected that 80% of all products sold within the Union would carry CE Marking by the year 2005. This will allow businesses (when complying) to trade in a market of approximately 450 million people.

Company Profiles

Laicon Consulting Services Inc. – Based in Orlando Florida, and operating since 2009; Laicon are a CE consulting company that utilize actual and practical knowledge that has been gained over the years to advise, guide and manage the CE requirements for a variety of National & International companies (typically Machinery, but also includes electrical equipment and other generic products that are covered by the European New Approach Directives). Each project is tailored to meet the customers’ needs and can range from generic CE advice and guidance, up to and including a full CE Project that would include the Design Review, Risk Assessments, Electrical Noise & EMC Testing, drafting of the equipment Name Plate(s), drafting the equipment Declaration of Conformity and building the relevant equipment Technical Construction File (TCF).

Hold Tech Files – Based in the Republic of Ireland, within the European Union, they hold Technical Files and Technical Documentation securely on behalf of companies for CE Marking of machinery and products and for homologation of vehicles. Hold Tech Files acts as an EU Authorised Representative for CE Marking and as a Manufacturer’s Representative for vehicle homologation. For the Machinery Directive, they can be named on EC Declarations of Conformity or Incorporation as the person authorised to compile the Technical File. Under EU Regulation 2019/1020, they act as an Authorized Representative and, therefore, the ‘economic operator’ in the EU.

Haumiller Engineering

60 YEARS OF ASSEMBLY AUTOMATION SUCCESS, AND COUNTING!

Contract manufacturers and OEMs trust Haumiller to deliver high-speed automated assembly machines for high-volume disposable products. We provide custom machinery for a range of industries, including manufacturers of life sciences, medical devices, consumer products, food/beverage, electrical connectors and specialized aerosol equipment.

These companies come to us for assembly machinery that is designed, built and tested to meet their specific needs for speed, quality, tolerance, inspection and other parameters. It must be on time, and it has to perform to the highest standards – or time and money will be lost.

That’s no small task, but it’s what we thrive on. Since the day we were founded in 1963 by Cliff Haumiller, we have produced the most efficient and reliable automation equipment on the market, helping industry leaders stay at top productivity to meet their toughest market challenges.

Today, we operate out of an 87,000 square foot state-of-the-art facility with world-class capabilities that most competitors only aspire to. We’re proud to put the Haumiller brand on your equipment, because we’re quite clear what we stand for:

- Personal Attention. We have been 100% employee-owned since 1986. Our culture of ownership means stability for our company and the dedication and unique focus of our employees. There is no doubt, our employees are the reason for our success. We invest in our employees, which allows us to produce better equipment for our customers. Above all, we emphasize open communication with both employees and customers to ensure potential issues are proactively addressed and resolved.

- Quality. Haumiller is ISO 9001-2015 certified, meaning we consistently build quality into everything we do. We particularly focus on risk management, as evidenced by our meticulous approach to design, documentation and testing of your assembly equipment. We take a long-term perspective, designing and building automation machinery that will perform for as long as you need and providing the quality of product and service that builds long term relationships.

- Reliability. Haumiller equipment has a reputation – for ease of operation, ease of maintenance and ease of changeovers. Our machines can be run by varying levels of skill in your

labor force. Our exceptional documentation for all machine parts mean you don’t have to pull machines out of production for any significant time to maintain them. And changeovers are fast, with no sensitive adjustments or fine tuning needed, ensuring you can ramp back up to full production quickly. - High Yields. Our equipment produces exceptionally high yields, however you measure it. This means our machines fill more boxes for you!

- Delivery. Our delivery record is second to none. We make sure you can get to market when you need to.

Case Study of Haumiller Engineering: Blade Assembly Machine

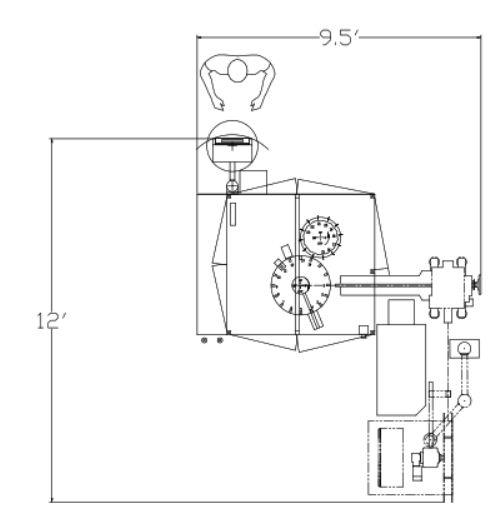

Brief Machine Description – The system consists of one indexing module attached to a laser module and a blade feed module. The system will punch pre-bend blade supports off of a reeled ribbon, weld the support onto a razor blade, then stack the welded blades into the customer supplied bayonet. The system is self-contained in that there are no tracks shared with other facility machines. Parts will exit via bayonet. The product components are fed by a de-reeler and stamping press, probed for presence, and proper assembly, and rejects incomplete or incorrectly assembled product components. Acceptable parts are ejected via bayonet.

For this particular project, we settled on the following procedures to expedite and ensure a smooth CE certification process.

Step 1 – Design Review:

(a) By way of a virtual conference call, wherein Haumiller displayed a 3-D model of the equipment, Laicon was able to determine the applicable EU Directives (Machinery Directive 2006/42/EC and the EMC Directive 2014/30/EU), and subsequently which EN Standards would be applicable to this type of equipment. One of the goals at this stage is to determine if there are any C-Type EN standards applicable to the equipment (C-Type Standard is a Machine, or process specific Standard, such as Hydraulic Press, or thermoprocessing, etc). Note – As it was determined that there were no specific C-Type Standards applicable to the equipment, the route of CE compliance was agreed to be with the EHSR’s (Essential Health and Safety Requirements of the Machinery Directive), but also by referencing applicable A-Type and B-Type EN Standards e.g., EN ISO 12100 (Risk Assessment Standard), EN ISO 13849-1 & EN ISO 13849-2 (Safety Circuit design, Validation and verification Standards), EN ISO 13850 (E-Stop Standard), EN ISO 11418 (Prevention of unexpected start-up Standard), EN ISO 11419 (Interlock Standard), EN ISO 14120 (Guarding Standard) and EN 60204-1 (Electrical Safety Standard) to name just a few.

(b) During the Design review, Laicon were able to identify various Hazards and/or non-compliance issues, such as Guarding shortcomings wherein there was access to hazardous moving parts off machinery; electrical component selection (e.g., Motors and controllers now have to comply with the Energy Efficiency EU Regulation 2019/1781); colour coding for wiring (Earth Conductor must be Green/Yellow 50/50 +/- 20%); the requirement for use ofCE marked critical components and Safety components, design requirements for the Safety Circuit. Note – As Laicon and Haumiller have been operating together for over 10 years, and subsequently Haumiller have become even more proficient and designing CE compliant machinery, there were very few hazards and/or non-compliance issues identified during this particular design review, although the process still had value as we were also able to identify other items such as (i) how the Operators will interact with the equipment, (ii) Maintenance tasks, (iii) access requirements for product change/clearing a jam/ maintenance and cleaning, (iv) the Technical documentation requirements for the equipment Technical Construction File (TCF), as well as (v) planning out the site visit for final assessment and testing.

Note – I believe that it is worth mentioning at this point that the Laicon Engineers utilize a specific Risk Management software that not only allows them to conduct and record the Risk Assessment information (including the ability to add photographs to each Risk Assessment), but also allows them to generate/export various reports that are then added to the equipment Technical Construction File e.g., EHSR Check List, Electrical Check List, Risk Assessments Action List, generate a draft DoC for the equipment, log all project details including the OEM and machine details, export an EN 13849-1 Assessment Report, and many more reports/check lists that can be configured into the Software by working with the Software vendor at www.compliancerisksoftware.co.uk

(c) During the Design review communications phase, Laicon identified the requirement for Haumiller to ensure that they had a European Authorized Representative (EUAR) in mind for their equipment. Information note – Due to the July 2021 EU Regulation 2019/1020, CE marked products (including machinery), must have a written mandate between the OEM and the EUAR to confirm who, in Europe, is taking responsibility for their equipment. Note – As many International OEM’s are not located in Europe, they do not fall directly under European legislation; subsequently, by naming a EUAR (who is legal and resident within the European Economic Area – EEA), the non-European OEM can meet the requirements of this Regulation. Subsequently, Laicon have established a working relationship with Hold Tech Files (based in the Republic of Ireland, and thus part of the EU) who will act as the EUAR for our customers; in the knowledge that Laicon have been instrumental in assisting with the CE Certification process, completed the Risk Assessments, testing and compiled the TCF. Note – See Hold Tech Files company description within this Case Study Report.

(d) The Design Review was concluded by Laicon submitting a design review report to Haumiller to confirm the findings during the Design assessment and to confirm the list of Technical Documentation requirements for inclusion into the equipment Technical Construction File (this report was supplemented with a document check list provided by Laicon that also provides information and guidance on content of the equipment Instruction Manual). Note – As Haumiller are an ISO 9001 Certified company, Laicon already had a high level of confidence that the Technical documentational requirements would be met, as per previous CE projects between Haumiller, Laicon and Hold Tech Files

Observation Note – We would recommend that a Design Review be conducted at least 6 months prior to the actual CE inspection and testing, further out if at all possible i.e., the sooner the hazards and/or non-compliance issues can be identified, the sooner they can be either designed out, or control measures for mitigation can be designed in.

Step 2 –Initial Project management:

(a) Laicon prefer to have an open line of communication with the OEM to ensure that their Engineers are able to ask specific CE related questions during the Design and Build phase of the equipment; this method of open communication between Haumiller and Laicon has been proven to reduce the amount of remedial work requirements during the actual CE assessment and testing phase of the CE Project.

(b) In our experience, without the open lines of communication at the early stages of the project, there is an element of risk that a design engineer might ‘believe’ that he/she is following the correct path for CE compliance, but it can ultimately transpire that they have misread, or misunderstood, information provided in the Design Review Report and/or check lists provided by Laicon.

Step 3 – CE Audit and testing of the equipment:

On a pre-arranged/agreed date between Haumiller and Laicon, the Laicon CE consultant Engineer and Laicon Test Engineer arrived on-site to conduct the CE Inspection and testing, which effectively included the following process/actions:-

(a) Risk assessment of the machine – The Laicon CE consultant was provided a desk, chair and power supply in close proximity to the Haumiller blade assembly machine to allow for a visual inspection of the machine in both passive and operational modes, the inspection and testing lasted for a total period of 5 Days (3 Days CE Assessment and inspection and 2 Days of Testing). Haumiller provided several Engineers to operate and discuss the functions of the machine with Laicon during the Risk Assessment phase of the Project. Risk Assessments were conducted in accordance with EN ISO 12100 (Risk Assessment Standard). The deliverable from the Risk Assessment was an Action List (a ‘To Do List’) of residual hazards and non-compliance issues that were apparent on the machine. The Action List was discussed in detail with the OEM’s design Engineers and Technical writers on the last day of the visit by the CE consultant Engineer, thus allowing for the CE consultant to explain what was on the Action List, why it was on there, and (in layman’s terms), what needed to be done to put it right and bring the equipment into CE compliance. The action List included photo(s) of the items to further identify the exact nature of the hazard and/or non-compliance issues. Note – Sign-off of the Action List items is conducted post-site visit by Laicon once we received the photographic and documentational evidence that the Action List ‘control actions’ had been implemented by Haumiller.

Note – The above process allows the Laicon CE Consultant Engineer to identify hazards and/or non-compliance issues and offer solutions based on his/her knowledge of the applicable EN Standards (the EN Standards are utilized as guidance tools to assist meeting compliance to the EHSR’s of the Machinery Directive 2006/42/EC). Subsequently, by implementing the Control actions identified on the Laicon Action List, the OEM is able to bring the equipment into compliance, thus ensuring a CE compliant and safe machine

(b) Testing of the machine – (i) Electrical safety testing was completed by Laicon, as per the requirements of EN 60204-1, Section 18, this generated 2 x electrical test reports that were then added to the equipment TCF to demonstrate that the equipment is ‘electrically safe’, as required by the Machinery Directive EHSR 1.5.1. (ii) In addition, Noise testing was also conducted around the machine to identify and record the maximum acoustic noise emitted by the machine, again the Noise Test report was included into the equipment TCF. (iii) Finally, the equipment underwent 2 days of EMC testing (Electromagnetic Compatibility testing), wherein the resultant EMC Test Report was also added to the equipment TCF to help demonstrate compliance to the EMC Directive 2014/30/EU.

(c) Safety Circuit EN 13849-1 evaluation and functional testing – During the Design Review process, Laicon and Haumiller had discussed, and agreed, the various Safety Functions of the machine and settled upon the Performance Level requirements (PLr’s) for these Safety Functions i.e., in this case the E-Stop and guard Interlock Safety Circuits. Subsequently, during the CE audit, Laicon and Haumiller Engineers were able to complete functional testing of the Safety Circuit, as well as review of the schematics to ensure that the design appeared to be as it should be. This action was supplemented by sending all relevant safety circuit information to the Laicon validation engineer, who then conducted a Sistema validation to confirm that the PLr’s were in fact being met by design e.g., Safety Circuit design, reliability of the Safety Components utilized, demand rates on the safety devices, etc. The Laicon Validation engineer then provided a Sistema validation report for inclusion into the equipment TCF.

(d) Documentation and TCF – (i) As Laicon had already provided guidance on the content of the equipment Instruction Manual, Laicon then conducted an on-site review of the equipment Instruction Manual to confirm all relevant information was present. The Action List also identified specific information that was to be contained within the Instruction Manual, as required by the Machinery Directive EHSR 1.7.4.2. The post-visit Project management included a final review of the equipment Instruction Manual before it was added to the TCF. (ii) Other documentation that had previously been identified in the CE document check list provided by Laicon included schematics (Electrical & Pneumatic); Machine drawings; Declarations of Conformity for CE marked components utilized in the machine build and Technical data sheets for components utilized on the equipment (DoC’s & Tech Data sheets are classed as supporting documentation to the OEM’s claim to CE compliance); an Electrical & Mechanical BoM (Bill of Materials) and other such documentation based on Annex VII of the Machinery Directive; Haumiller were able to provide a large percentage of these documents during the site visit, with the remaining documents provided as part of the post-visit project management. The documents provided by Haumiller were then added to the Technical Construction File that Laicon generated for the equipment.

(e) Machine Name Plates and equipment Declaration of Conformity – (i) As the Laicon CE consultant progressed through the CE audit, they were then able to then generate a draft version of Electrical Name Plate for the main Electrical enclosure. Note – The information included on the Electrical name plate is highlighted in EN 60204-1, Clause 16.4. Haumiller then had the Name Plate manufactured and permanently affixed in close proximity to the mains disconnect switch and sent photographic evidence to Laicon to allow them to sign-off this particular Action List item. (ii) Laicon was also able to generate a draft version of the Machine Name Plate, as per the Machinery Directive EHSR 1.7.3. Haumiller had this Name Plate manufactured and affixed in a visually obvious and permanent location on the machine superstructure. (iii) Finally, based on the EN Standards that were referenced during the CE audit, and the fact that Haumiller had already agreed for Hold Tech Files to be their European Authorized Representative, Laicon were also able to complete a draft version of the equipment Declaration of Conformity (DoC) for Haumiller’s approval. Once all Action List items had been completed, Haumiller then had a senior manager sign and date the equipment DoC and forwarded a copy to Laicon so that it could be added to the equipment TCF, a copy was added to the equipment Instruction Manual (as required by the Machinery Directive), and a copy was added to the shipping paperwork when the equipment shipped to the EU for the Customs & Excise at the European port of entry.

Step 4 –Post site visit Project management:

The post site visit project management phase included the signing-off of all action list items. Note – This was made possible by Haumiller providing all relevant photographic and documentational evidence to demonstrate that each action list item ‘control actions’, had in-fact been implemented.

In addition to the Action List sign-off phase, Laicon continued to build, and were subsequently able to complete, the equipment Technical Construction File by utilizing the information provided by Haumiller as well as the information obtained during the CE Audit and testing phase of the project.

Ultimately, this CE project between Laicon, Haumiller and Hold Tech Files, demonstrated that, although the path to CE compliance may be multi-facetted and extensive, it is possible to navigate the process successfully if it is planned in advance and executed with personnel committed to producing a world class, and safe, machine.